- Home

- Deceptions

- Solar

- Thermal Audit

- Ventilation

- Sensors

- Governance

- Environment

- Reference

- Contact

- News

Consumer Warning

Venmar HRV Failures

(also sold as Venmar, Flair ,vanEE, Conformax, NuTone, Carrier, Bryant, Payne, Heil, York, Sears OPTIMUM, Guardian by Broan and more ...)

IMPORTANT UPDATE, Feb 2012 -- A burning Van EE has been caught in the act. When I wrote this up a year ago I contacted regulatory agencies in the USA and Canada and told them exactly how this can happen and gave them a copy of the page, but they closed their investigations and I never was able to get a copy of the manufacturers rebuttal to the case.

"On February 4, 2012, my van EE 90 H overheated at 12:30 a.m. The unit was emitting smoke and the internal components were melting. Luckily, we were home and detected the issue. I immediately unplugged the unit, removed the suspended box and placed it outside. The unit was nearly on fire. The unit serial number indicates it was built in 200511. It has been in operation since 2006. I am very concerned about the associated fire risk. I live in a new subdivision and our houses are all equipped with the same unit. I have called vanEE and my HVAC installer. I was glad to find your site talking about the issues. E mail me if you have any questions. Thanks."

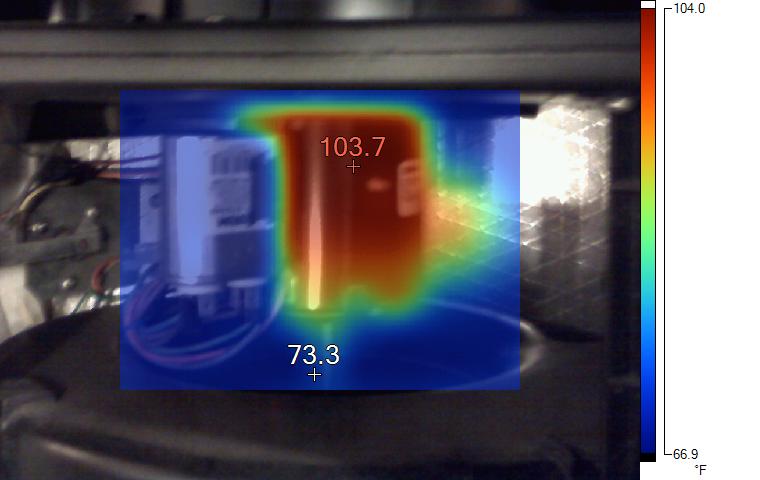

The image below is an infrared photo of a Venmar running at low speed with a newly replaced motor. The only electric component that gets hot is the two speed fan motor which is bolted to a plastic fan housing. There is also a small actuator motor that controls the recirculation damper, but it doesn't heat up even when operated continuously. The oval siver object to the left of the red motor is a capacitor in a metal can, unlike the round black plastic one that melted below.

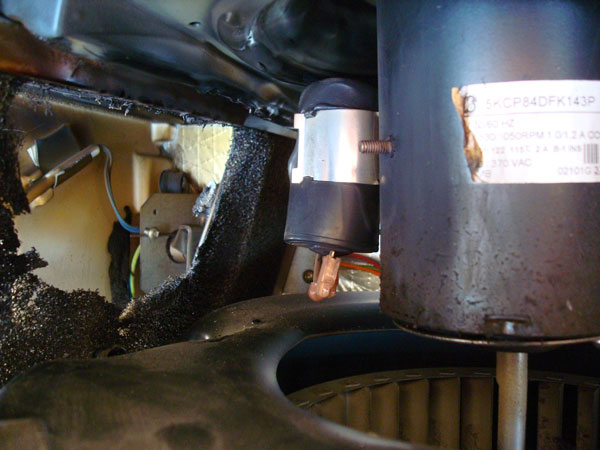

The photos below are of a Venmar HRV unit that burnt.

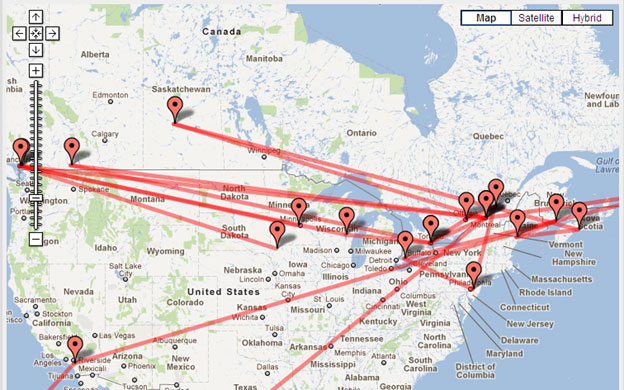

I have been receiving a lot of really detailed Venmar complaints and detailed comments are unusual. Most web pages on this site generate a message of thanks or intense diatribes of hate whereas this one has genuinely concerned people who clearly document serial numbers, overheating issues and battles with Venmar's customer service. Here is a map of the approximate location of the last 25 detailed complaints I have received. This is a Canada-USA problem.

Note: The article below was written almost exactly one year before the fire photos arrived. Venmar knows about this as do the US and Canadian federal agencies that are supposed to force the recall of dangerous products.

Venmar has produced dangerous heat exchangers, many of which have been subject to recall. However, there are many more that are not covered by the recall but are also subject to premature failure. The recall from the U.S. Consumer Product Safety Commission needs to be expanded, but companies like Venmar do not recall defective products willingly nor admit fault.

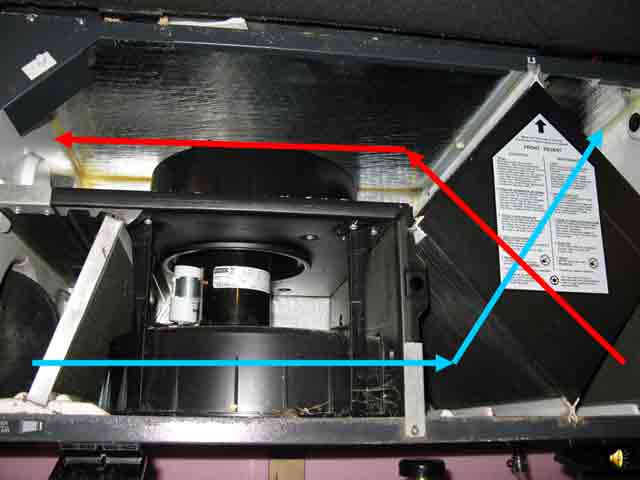

The central problems revolves around a poorly chosen fan motor and the extensive use of combustible materials inside the heat excahnger unit. The motor is an induction motor manufactured by Fasco (now owned by Regal Beloit) that fails prematurely when used as the blower motor in Venmar HRV units. After having three of these motors fail in 4 years, I created this web page as a consumer service. I also have immediate neighbors that have had similar failures so the chance that my unit was an anomaly is highly unlikely. A much more probable scenario is that there are thousands of these units in new homes with failed motors and the average consumer has no idea that they aren't working. The primary risks are poor indoor air quality, excessive carbon dioxide levels, mold growth and in some cases the fan motors with failed bearings self destruct and get very hot until the thermal fuse blows. Since the motor is bolted to a plastic housing, fire is possible. Wihout working ventilation, if the moisture levels in your house get too high, even your wall studs will rot.

Symptoms:

- Excessive vibrations that can be felt in the house. For example, if it is mounted from hanging chains in the basement, and you lie on the sofa on the living room above, you will clearly hear the vibrations. If you disconnect the return air duct, you will hear definite pulsing in the air stream. If flexible ducts are attached to the unit you will see them shaking. The vibrations are due to play in the sleeve bearings.

- The vibration problem goes away after a few weeks followed by silence. At this point the motor has seized or the rotor has smashed the core, overheated (above 300°F), blown the thermal fuse and the unit is no longer functional.

- If the bearings seize, the motor will get very hot. You can verify overheating by unplugging the unit and then opening the door and touching the body of the motor quickly and lightly, but be careful. Use an infrared thermometer if you have one. If it is uncomfortably hot, do not plug it back in.

- In some cases, the motor mechanically self-destructs, overheats and blows the thermal fuse inside. In this case, once the initial overheating is over, there is no additional fire hazard. However you have a piece of junk and may have humidity problems in the house due to poor ventilation and perhaps suffer mold damage.

A well designed fan motor should last decades -- these motors are lucky to run continuously for three years, or perhaps five years if you have the heat exchanger on a timer. They have inferior sleeve bearings rather than ball bearings and once the bearing wears, the motor's rotor can strike the core and destroy it. If you look at products like the in-line duct fans from Fantech you will see they use an external rotor motor for better cooling. Fantech uses a high quality motor from ebm-papst, other great choices would have included the IPM (internal permanent magnet motors) which are standard in Japan and responsible for the incredible performance of the Toyota Prius, hysteresis motors or electrically commutated DC motors.

The photo below shows the inside of a Venmar Constructo. The motor is in the center of the photo and has a label on it with the manufacturer FASCO clearly visible. If the cover is open, the motor will not run unless you press the white button in the upper left corner of the picture. This button is pressed automatically when you close the front cover.

The picture below (failed unit number one) is the assembly that is replaced in its entirety every time the motor bearings seize. This is great for the service technician (two screws are all that need to be removed) but terrible for the customer that gets a huge repair bill. By huge, I mean service calls in the $250 to $300 range, and perhaps every year.

The problem motor (this is an image of failed motor number three!). It is marked Model: 71902271, Type U90SB1, Class: B AO and part number 06946.

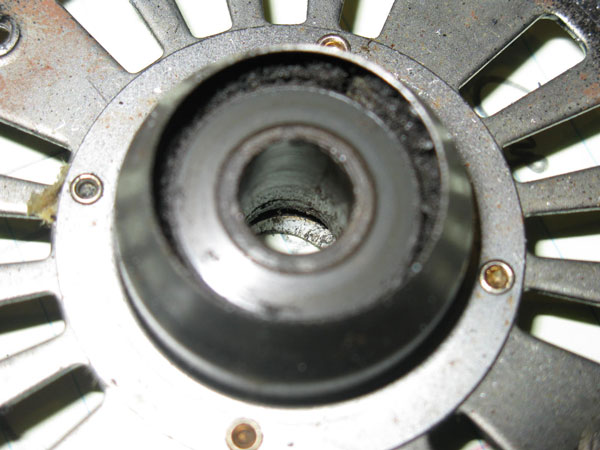

The image below shows a failed motor seal. The bearings have worn so much that the rotor has hit the core. Motors like these should have sturdy ball bearings instead of inferior sleeve bearings, especially when used in an application with extreme variations in temperature. In winter, the incoming air can be -25°C and in the summer it can be close to +40°C. The decision not to use a motor with better bearings was likely motivated by profit although stupidity is not out of the question.

Here is a what the sleeve bearing looks like.

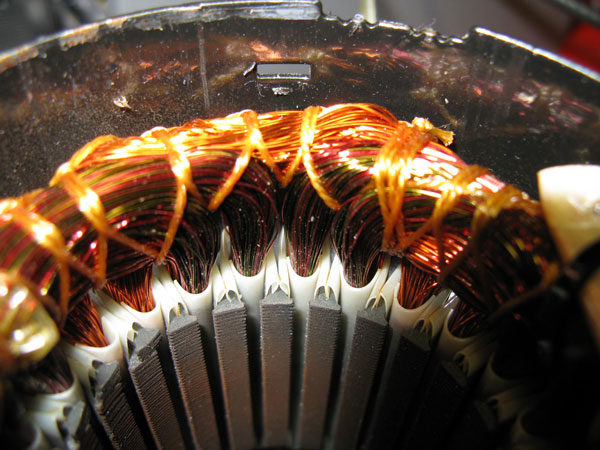

When the bearings wear excessively after a year or two of operation, the rotor of the motor starts rubbing or beating against the stator and you see this:

Unfortunately, the rotor, which on an induction motor is a sturdy hunk of iron and aluminum bars, destroys anything it contacts. The image below shows the steel laminations have been destroyed. The vertical slots were originally in straight lines, not broken up as in the image below. Since their edges are sharp, they can easily cut through the stator winding insulation and short them together, creating an electric heating circuit instead of a motor. This has the potential to get much hotter than the motor would if you were to simply stall it by having the bearings seize. This motor is bolted onto a rubber seal which can burn -- so this is a recipe for disaster.

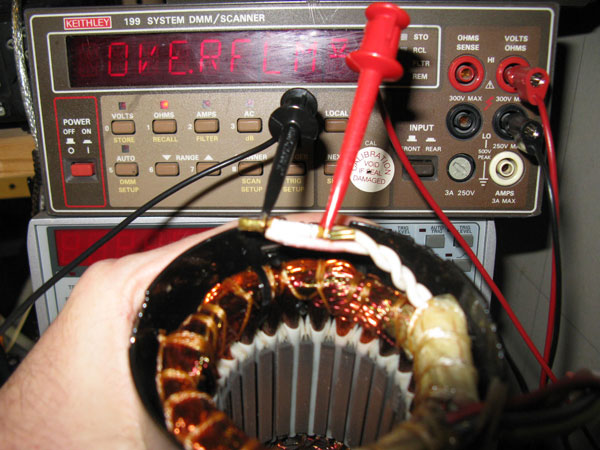

Now looking a little close at the problem, notice the location of the thermal protection fuse. If the windings that overheat and short (and in this case, the destroyed section of the core is directly opposite of the fuse) are on the other side, then it is going to take a while to blow.

The FASCO fuse is covered in the photo above with a plastic sleeve, but is exposed here. It cuts out at 5A or 150°C (300°F).

Now we test the fuse and see that is an open circuit (blown).

If you look closely at the picture above and the picture below, you can see that there are dark areas on the coils of copper wire where the clear insulation coating on the copper wire has charred.

So there you have it. One realistic sequence of events leading to a fire would be this:

- The sleeve bearings wear out (this has happened to me multiple times)

- The rotor smashes the core and cuts up or shorts out various windings (see photo above)

- The windings get very hot (see the charred insulation above)

- The windings that get the hottest just happen to be far away from the thermal fuse or you have an older motor that doesn't even have a thermal fuse. This would allow the motor to exceed 300°F.

- The ultra hot motor is mounted directly against a rubber ring (you can see it in the motor replacement instructions) and bolted to a plastic fan housing which can melt and burn.

- There is additional fuel available since the heat exchanger core is also plastic

- Presto -- box with fire coming out of it to burn your house down.

Don't worry too much, this isn't going to happen very often - just like babies don't killed in drop side cribs very often.

Obvious ways to reduce this possibility are:

- Use a motor with quality ball bearings that last decades between failures.

- Choose a motor where the rotor cannot destroy the core and shatter it like the one above

- Install a thermal cutoff that measures the temperature of the end of the motor that is bolted to the fan assembly.

- Do not bolt the motor directly to anything that can burn!

What Venmar needs to do:

- Design a upgraded fan assembly with a quality motor, and where the the worst case (motor draws 15A, the max before your wall socket blows and gets smoking hot) is attached to nonflammable parts and far enough away (via a heat sink or distance) that no plastic parts can possibly burn.

- Provide a free swap in replacement to all their customers or offer them a newer model for free.

- or offer a 100% refund of the list price (most people had it come with their house, so they don't have invoices) so that homeowners can trash it and buy something else.

What Venmar will likely do: Nothing. Unless they get sued or forced into another recall by government action. Like most corporations, they are sociopath's that are do whatever makes their shareholders the most money, regardless of the consequences to others. There are a few companies like Costco or Honda or founder owned businesses that still care about society but these are becoming rare exceptions.

If you have a broken Venmar, I encourage you to leave a message on this web site, and I will include your problem description or comments below. Also, if your seized motor is hot, unplug the unit and report it to your local consumer safety branch.

You can try complaining to Venmar customer support, but you will likely only receive a generic response asking you for repair invoices and details you don't have any more. The actual contents of your e-mails will be ignored, so make sure you save a copy of anything your send them. I recommend reporting them to your national safety branch as well as notifying Venmar by e-mail so that they cannot claim ignorance of the situation. This way, if you report a problem and your house burns down, they may be legally liable for damages.

Where to report your defective Venmar heat exchanger:

USA

Consumer Product Incident Report

Canada

Venmar e-mail address (More to come)

Ivanhoë Bouchard| Technicien service clientèle | Technician Customer Service

bouchardi@venmar.ca

Venmar Ventilation inc.

800-567-3855 / 819-477-6226 ext : 2633 Bureau / Office

800-567-1715 Téléc / Fax

Marlene Janelle| Chef d'équipe service technique | Technical Service Team Leader

Janellem@venmar.ca

Venmar Ventilation inc.

(800) 567-3855 ext :3532 Bureau / Office | (819) 475-2660 Télécopieur / Fax

What next?

I recommend you cut your losses and purchase a new heat exchanger from another manufacturer. Replacing motor assemblies ever year or two is a terrible waste of money. The 3.3" diameter, double shaft motor doesn't have many alternate suppliers so even if you want to try extracting it from the fan assembly yourself and have the tools, you will be stuck paying at least $130 for an identical FASCO motor (FASCO model R2-R462) which won't last any longer than the one you replaced. Amazon marketplace will likely have one available.

If your house doesn't feel stuffy, then you can probably get away with not having a heat exchanger at all. If your house is quite air tight (especially ones built to R2000 standards), then you do need something because your carbon dioxide (CO2) levels will be over 1000 ppm (parts per million) and your house will feel stuffy and stale. CO2 at 1000 ppm is not a health hazard, but isn't pleasant either - it is about the same as a completely full school classroom and the end of a lecture when the windows and door are closed. By comparison, fresh air is about 400 ppm CO2. A bigger problem is high humidity levels that could allow mold growth. If you were unfortunate enough to end up with a toxic mold colony, your house could be a total write off -- not as spectacular as burning down but just as catastrophic.

I don't have any particular manufacturer recommendations at this point other than to avoid Venmar. I have no doubt that some of Venmar's higher end products are better, but given that they are unwilling to stand behind their products, I would not trust them. Such a pity - I would have loved to promote a Canadian company that had some pride in their products and a commitment to customer service.

Replacement update:

I decided to replace the motor with this one for some experiments I wanted to do.

It is a Roto M brand R462. Unlike Venmar and Fasco, RotoM responded with a thoughtful reply to this web page which is rare and for that they deserve credit. Most large companies couldn't care less about individual consumers, despite their claims to the contrary.

The CSA mark LR6319, on the RotoM motor belongs to RBC Horizon d/b/a Fasco Industries, Inc. so this is only a label change.

There is no guarantee that this motor will fare any better in this application - only time will tell. If you would like to replace yourself, the see these motor replacement instructions.

Reader Comments

Comments: name = Jan

Venmar HRV with a PSC Motor Many thanks for your blog, it is both informative and interesting. However be aware the Venmar HRV you purchased has a notoriously inefficient, energy wasting, waste heat generating, really bad cheap PSC motor. Never purchase an HRV or ERV with a PSC motor. The reason it fails every two years is the enormous waste heat it generates (and wastes electricity, negating the benefit of HRV in the first place)which fries the motor and ruins the lubrication. Always insist on an ECM Electronically Commutated Motor. Quieter, much more energy efficient, runs cool not hot, less noisy, and lasts a very long time. Many quality HRVs are available with an ECM motor. Please alert your readership to this important difference. Products like the Venmar with the PSC are so bad they will cause readers to abandon their environmental interest. Some HRV manufacturers and installers choose PSC equipped HRVs to hit a low initial price point. You will be paying for it many times over, longer !

term. Contact Venmar and ask if they may have an ECM replacement for the awful PSC motor in your Venmar HRV; if not, I urge you to consider replacing the unit with an ECM equipped motor HRV. You will save the extra cost soon via lower electric bills, not having to buy a new motor every two years, less aggravation, less of your time wasted fixing the thing constantly.

comments = Hi, take a look at this HRV (for example) vs. the Venmar with a PSC inefficient motor:

UltimateAir ERV The UltimateAir RecoupAerator 200DX is the most efficient ERV sold in North America.

NLCPR Note: We have no experience with Ultimate Air products and cannot endorse anything I have never seen, but Jan's comments absolutely make sense. The Venmar unit above consumes about .120kW*24hr*365days*$0.12/kWh = $120 a year when running continuously, which is a lot of energy. Coupled with regular motor replacement, it barely makes sense to even use low end 'builders specials' like this. In order to get a decent return on your investment, motors that are much more efficient and longer lasting than those in the Venmar unit shown above are required.

Via Twitter:

Eric M. Savoie

Motor failure on my Venmar air exchanger (VanEE 90H Novo+) after less than 3 years. $500. Not a happy customer.

name = David Butler

Adding to what another commenter said, avoid buying ANY recovery ventilator with a PSC motor, even a good one. As it turns out, a PSC motor's fan power curve (CFM per watt) is the opposite of an ECM. Why is this important? HVI ratings are based on full power. Many HRV's are oversized intentionally to provide spot ventilation for bathrooms, but then operate at low speed 95% of the time. A PSC motor is already inefficient at full power (typically less than 1 CFM per watt), but they are even less efficient at low power (maybe only 0.5 CFM per watt. An ECM power curve is the inverse, so operating at full power may be 2 CFM per watt, but at low power may be closer to 3 CFM per watt.

name = Robert

Hi, I have an HVR Solo from Venmar and it's gonna be my third motor that the bearing have failed. I'm very upset about this cheap motor, they could use a better one and still make good money out of their units. I'm gonna try to have a new motor from Venmar for free or I'm looking to change the unit to a better company.

name = Patrick Poirier

I had the same problem 2 years ago, and yes Venmars are CRAP. Being from the region of Drummondville, I can say that about 90% of the homes built between 1980 and today (in the region) contain those heat exchangers and they seem good product (when you don't own one). Since I bought my first home, my opinion changed drastically, no clear documentation neither in french or english, not user-friendly-built, not good quality and poor efficiency. This sounds like a lousy business plan...

Wich I could be proud of a hometown company.

By the way, excellent site, the world would be a better place with more people like you.

Keep at it!

name = LARRY DUFORD

comments = Hi,Great article on your venmar motor replacement for a air exchange and just had the same thinking happen to me on the same kind of unit. Any advice on motors that would last longer and were I could purchase?

Thanks for your help!

name = Keith

comments = Since I now need to replace the motor in my VanEE90H (again) I was wondering how your RotoM replacement motor is doing??

Your site is quite informative. Maybe I should try to find something more reliable and just swap out the whole unit (this is motor # 3) but solution that is also pricey.

Thanks for your site info.

The information below is so that this page can easily be found by Google.

Venmar Constructo 2.0 specification sheet.

VENMAR AVS ERV CONSTRUCTO 2.0 QUATTRO

Part #45115

REPAIRS AND MAINTENANCE

Venmar AVS ERV Constructo Quattro modular design makes it

possible to remove all mechanical parts in less than 5 minutes. (to help the service companies quickly remove the guts and sell you and entire fan assembly rather than enable them to fix the motor. The motor is not easily removable from the fan assembly.) The low power consumption PSC motor is permanently

lubricated (when the lubricant fails, it simply seizes up. Low power in this context just means small, not efficient - PCS motors are wasteful). Even better, the entire motor sub-assembly can

be removed in less than a minute for easier maintenance. (this is true).

WARRANTY

The Venmar AVS ERV Constructo Quattro is protected by a

2-year warranty on parts only. (fans only last two years which is why we only give two years). The energy recovery core is covered by a 5-year warranty.

Venmar Ventilation Inc. Recalls Heat Recovery Ventilators Due to Fire Hazard

WASHINGTON, D.C. - The U.S. Consumer Product Safety Commission, in cooperation with the firm named below, today announced a voluntary recall of the following consumer product. Consumers should stop using recalled products immediately unless otherwise instructed. It is illegal to resell or attempt to resell a recalled consumer product.Name of product: Heat Recovery Ventilators

Units: About 75,000

Manufacturer: Venmar Ventilation Inc., of Quebec, Canada

Hazard: The motors in these units can overheat, posing a fire hazard.

Incidents/Injuries: Venmar Ventilation has received four reports of ventilator motors overheating resulting in fires causing extensive property damage. One incident in Michigan reportedly resulted in about $1 million in damages.

Description: Heat Recovery Ventilators are designed to exchange air between the inside and outside of a home in order to provide fresh air. The recall covers units made from 1991 through 2001, and have the following brand names and model numbers:

| Brand | Models |

|---|---|

| Venmar | AEXX, EARC, 1XX, 30X, 40X, 40XXX |

| Venmar AVS | 1.X, 2.X, 30XX, 55XX |

| Flair | 30, 30XX, 55, 55XX, 85115 |

| vänEE | 10, 1XX, 100X, 20, 20XX, 30XX, 90 |

| Conformax | 300, 350, 400 |

| NuTone | NUTR130 |

| Carrier Bryant |

VXXXXXXXXX, ERVXXXXXXX or HRVXXXXXXX |

| Payne Day & Night |

VXXXXXXXXX |

| Heil | HEILXXXXX |

| York | 5263554XXXX |

| Sears Brand | OPTIMUM |

| Guardian by Broan | 100X, 200X |

| Rheem Ruud Protech Weatherking |

84-ERV100, 84-ERV200, 84-HRV100, 84-HRV200 |

The model numbers are written on a silver or black label on the outside of panel. The "X" digit used in the model numbers can be either a letter or a number.

Sold by: Heating, plumbing and building supply distributors nationwide from January 1991 through December 2001 for between $700 and $2,500.

Manufactured in: Canada

Remedy: Consumers should immediately turn off and unplug their ventilators, and contact Venmar to receive instructions on how to participate in the recall. Venmar will provide a free safety device that will shut off the ventilator if the motor overheats.

Consumer Contact: For more information, contact Venmar Ventilation toll-free at (866) 441-4645 between 9 a.m. and 5 p.m. CT Monday through Friday, or visit the firm's Web site at www.venmar.ca

Short URL for this page: http://bit.ly/ic3BYh